How Can You Fly a Drone When It’s So Dusty You Can’t See? By Using a 3D Live Map

BY Zacc Dukowitz

23 August 2022Drone technology for flying in harsh industrial environments has come a long way over the last few years.

We now have drones that can fly in dangerous confined spaces and without GPS, allowing commercial pilots to operate inside deep mines or the interiors of huge industrial assets, like boilers or silos.

Credit: Flyability

But one of the most common challenges for flying in these types of places is also the most basic: dust.

Even a tough, rugged drone made to fly inside a harsh environment will still be blinded by dust—either by dust kicked up by the props, dust that’s already present, or both—making flying almost impossible. So how do you fly when your drone’s visual feed is blind?

By using a 3D Live Map.

3D Live Maps are 3D maps created in real time, as the drone flies, which pilots can use to fly even when their visual feed is basically blind.

A 3D Live Map on Flyability’s Elios 3 pilot tablet (live visual feed appears in the lower right)

3D Live Maps maps are made using LiDAR data and SLAM (simultaneous localization and mapping), an algorithm that allows robots to locate themselves in three-dimensional space as they move through it, and create a map of it.

Flyability’s Elios 3 indoor drone comes with a LiDAR sensor and a proprietary SLAM engine called FlyAware, allowing it to create 3D Live Maps. And these maps are opening up new use cases for heavy duty commercial operations that might otherwise be impossible due to dust.

Here’s how the Elios 3 creates 3D maps as it flies:

- While in flight, the LiDAR sensor on the Elios 3 acts as a centimeter-accurate indoor GPS, sensing the drone’s surroundings.

- FlyAware (Flyability’s SLAM engine) uses this data to create a 3D map of the space it’s moving through, layering on more detail as the drone gathers more data.

Elios 3 Used for Cement Plant Stockpile Measurement

Of all the industries that face issues with dust for their drone operations, cement is one of the most challenging.

Picture taken by the Elios 3 inside a silo at a cement plant

Cement plants are incredibly dusty places, with all their operations inundated by different kinds of particulates made as a result of the cement production process.

In a recent mission, the Elios 3 was used at a cement plant in France to calculate the amount of a material called clinker that was stored in one of its silos.

The typical approach for these calculations was to have one of the plant’s workers climb onto a rickety platform about 80 feet in the air, in the dark of the silo, and poke a hold down into the clinker with a very long pole. Using approximate measurements from the pole, the worker would then estimate how much clinker there was in the silo.

The platform workers stand on captured by the Elios 3 (3D Live Map appears in lower right)

These measurements are important to production, since clinker is an essential ingredient for making cement.

The plant’s owners wanted to see if they could improve this potentially dangerous and inexact process, so they asked Flyability to test the Elios 3 to see if it could measure the clinker using 3D mapping.

The Elios 3 was chosen for this test stockpile calculation because it could operate in the extremely dusty environment of the silo—a place where it was so dusty that the drone’s visual camera would be almost completely blind while flying.

Outcome from the Mission

The Elios 3 was able to operate well inside the silo despite the dusty conditions, and was quickly able to calculate the volume of clinker in the silo.

3D Live Map inside the silo (poor visibility shown in visual feed)

In ten minutes, the Elios 3 collected all the data needed to make the stockpile calculation. It took another 20 minutes of post-processing with the software GeoSLAM Connect to produce the stockpile measurement that the cement plant needed, making for a total of 30 minutes required for the effort.

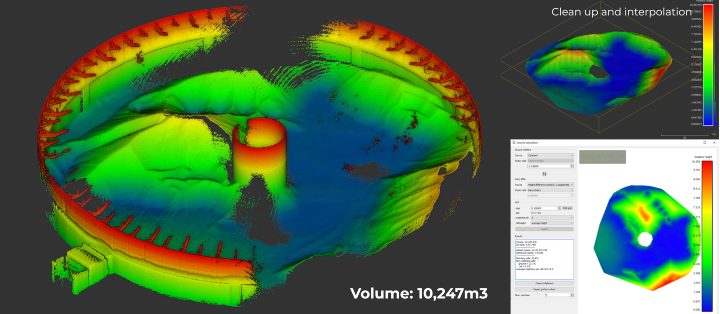

This image shows the output from the stockpile measurement:

In addition to being safer and quicker than the manual method typically used to measure the clinker, which required a worker to stand on a platform and poke a stick into the material, the measurement was also much more accurate.

Check out this 3D fly through of the clinker silo made with LiDAR data collected by the Elios 3:

Five years ago, flying in highly dusty environments may have simply seemed impossible. But today, thanks to the continued advances in drone technology, it’s not only possible, it can be done by drone pilots with relatively limited experience.

As drone technology develops, the ability to visualize spaces using LiDAR data while the drone is in flight will only continue to improve, opening up more and more places where drones can provide value in industrial scenarios.