Powerline Inspection Drones: An In-Depth Guide [New for 2026]

BY Zacc Dukowitz

22 December 2025Powerline inspection drones support utilities by capturing high‑quality inspection data quickly and safely along energized corridors.

Inspectors and maintenance teams use this data to find potential issues that might require maintenance or monitoring.

The need for drones in powerline inspections is huge. The U.S. power grid spans hundreds of thousands of miles of transmission lines, much of it aging and exposed to extreme weather—and drones can help speed inspections, while also making them less expensive.

Credit: Inspired Flight Technologies

Utilities are adopting powerline inspection drones at scale to reduce climbs and helicopter sorties, speed post‑storm assessments, and standardize documentation for maintenance and compliance.

The result? Faster inspections, improved safety for crews, and meaningful cost savings over legacy methods.

This guide will walk you through what powerline inspection drones are, how they’re used, the top platforms on the market, and more.

Here’s a menu in case you’d like to jump around:

- What Is a Powerline Inspection Drone?

- 3 Reasons Utilities Are Switching to Drone Powerline Inspections

- The Top Powerline Inspection Drones [New for 2026]

- Powerline Drone Inspection Software & Apps

- Drone Powerline Inspection Costs

- Jobs & Careers in Drone Powerline Inspections

- Powerline Inspection Drones FAQ

What Is A Powerline Inspection Drone?

A powerline inspection drone is any UAV that flies near conductors, towers, and hardware, capturing detailed inspection data on electrical transmission and distribution infrastructure.

Most commonly, this data will be visual and thermal. But it could also be LiDAR, for 3D modeling and vegetation clearance checks.

These drones are designed to operate near energized lines, towers, and hardware, providing clear visuals without the need for direct human contact.

Their core capability is to document the condition of powerlines and related components from a safe distance.

- High-resolution RGB (i.e., visual) cameras capture sharp imagery of insulators, conductors, and fittings.

- Thermal sensors detect hotspots caused by loose connections or overloaded circuits.

- LiDAR data provides the raw information to build precise 3D models of towers and surrounding vegetation, helping utilities identify clearance issues.

Some platforms also carry corona discharge detectors, which visualize partial electrical discharges invisible to the naked eye.

Credit: DJI

For larger networks, Beyond Visual Line of Sight (BVLOS) operations can allow drones to cover long corridors in fewer flights. When permitted, BVLOS missions significantly increase the efficiency of drone powerline inspections by reducing launch and landing cycles.

Drone powerline inspection flights can be manual or automated.

Manual control gives pilots flexibility to investigate anomalies or hard-to-reach angles, while automated flight paths follow pre-programmed routes that ensure consistent coverage and repeatable data collection. And many utilities blend both methods—using automation for routine surveys and manual control for targeted inspections.

Whether it’s flown manually or autonomously, a powerline inspection drone offers utilities a safer, faster, and more cost-effective way to monitor the health of their grid.

3 Reasons Utilities Are Switching to Drone Powerline Inspections

Over the last few years, power and utility companies all over the U.S.—and the world—have been adopting drones for powerline inspections at scale.

Here are the three main reasons why:

1. Safety Improvements

Drones keep workers out of harm’s way by reducing or eliminating the need to climb towers, enter energized zones, or operate from helicopters. They allow crews to inspect assets from a safe distance while still collecting detailed imagery.

By allowing maintenance teams to collect data remotely, drones eliminate the need for personnel to place themselves in harm’s way to collect inspection data, removing the risk of falls, electrocution, and aviation accidents. (They’ll still need to climb for the maintenance itself, of course—but eliminating manual data collection is a huge safety improvement in the overall process.)

2. Speed & Efficiency Gains

Automated flight paths allow operators to preprogram routes along spans and towers, ensuring consistent coverage and repeatable results. With BVLOS approvals, a single crew can inspect long stretches of transmission or distribution lines in fewer flights, reducing downtime between launch and landing cycles.

AI-powered software accelerates the review process by flagging potential faults—such as cracked insulators, loose fittings, or vegetation encroachment—so engineers can focus on decision-making rather than sifting through thousands of images.

This combination of automation and analytics makes it possible to turn inspections around faster, supporting quicker repairs and proactive maintenance schedules.

3. Cost Reductions

Using helicopters for powerline inspections carries the cost of fuel, pilots, mobilization, and support crews, while ground inspections demand trucks, traffic control, and labor-intensive climbing.

These methods can also require planned outages for safety, adding expensive downtime costs to an already costly process.

Drone powerline inspection shifts much of this expense to smaller aircraft, compact teams, and software tools—often allowing inspections without taking lines out of service. And as programs mature, utilities can drive costs down further with standardized flight plans, in-house training, and automated analytics—delivering equal or better data quality than traditional methods while also reducing inspection timelines and costly downtime.

The Top Powerline Inspection Drones [New for 2025]

Powerline inspection drones come in many shapes and sizes, from rugged multirotors built for close-up visual work to long range drones with fixed-wing designs made for mapping and corridor surveys.

Choosing the right model depends on mission needs, payload requirements, and environmental conditions.

This chart provides an overview of our top picks:

| Model | Flight Time | Payload Options | Approx. Cost | Ideal Use Case |

|---|---|---|---|---|

| Skydio X10 | Up to 40 minutes | Visual zoom camera, thermal imaging | $15,000–$20,000 | Close-range visual and thermal inspections with strong autonomy in complex environments |

| DJI Matrice 350 RTK | Up to 55 minutes | Zenmuse H20T, H20N, P1, L1 | $14,000–$18,000 (base, no payload) | High-precision, multi-payload inspections for transmission and distribution networks |

| Inspired Flight IF800 Tomcat | Up to 54 minutes | Multiple third-party payloads | $25,000–$30,000 | NDAA-compliant missions and inspections in regulated or sensitive environments |

| senseFly eBee X | Up to 50-60 minutes | RGB and multispectral camera options | $13,000–$16,000 | Large-area mapping and vegetation encroachment surveys along transmission corridors |

Here’s more information on each drone from the chart:

1. Skydio X10

The Skydio X10 is built for autonomous inspections in complex environments. Its AI-powered obstacle avoidance and precision navigation make it ideal for flying close to powerlines and structures, even in tight corridors.

Top Use Cases:

- Close-range visual and thermal inspections of powerlines

- Automated substation surveys

- Bridge and infrastructure inspections

- In areas with limited GPS

Key Specs:

- Flight time. Up to 40 minutes

- Payload options. Visual zoom camera, thermal imaging

- Autonomy. Full 360-degree obstacle avoidance

- Weather resistance. IP55 rated

Learn more about the Skydio X10.

2. DJI Matrice 350 RTK

Watch this video on YouTube

The DJI Matrice 350 RTK is a heavy-lift inspection platform with advanced RTK positioning for high-precision data capture. It supports multiple payloads, making it a versatile choice for utilities with diverse inspection needs.

Top Use Cases:

- Transmission and distribution line inspections

- Thermal imaging for fault detection

- Vegetation management surveys

- 3D modeling of infrastructure

Key Specs:

- Flight time. Up to 55 minutes

- Payload capacity. Up to 2.7 kg

- Camera options. Zenmuse H20T, H20N, P1, L1

- Range. 12.4 miles (20 km)

Learn more about the DJI Matrice 350 RTK.

3. Inspired Flight IF800 Tomcat

Watch this video on YouTube

The Inspired Flight IF800 Tomcat is a U.S.-made, NDAA-compliant inspection platform. Its rugged build and compatibility with heavy payloads make it a strong option for utilities needing compliance with federal procurement rules.

Top Use Cases:

- High-resolution visual inspections of transmission lines

- Thermal imaging for fault detection

- Surveying in sensitive or regulated areas

- Operations requiring NDAA-compliant hardware

Key Specs:

- Flight time. Up to 54 minutes

- Payload capacity. Up to 6.6 pounds (3 kg)

- Camera options. Multiple third-party compatible payloads

- Made in USA. NDAA compliant

Learn more about the Inspired Flight IF800 Tomcat.

4. eBee X

Watch this video on YouTube

The senseFly eBee X is a long-endurance fixed-wing mapping drone capable of covering large areas in a single flight. It’s well-suited for corridor mapping along transmission lines and other large-scale utility surveys.

Top Use Cases:

- Large-area mapping of transmission corridors

- Vegetation encroachment surveys

- Pre-construction route planning

- Environmental monitoring along utility rights-of-way

Key Specs:

- Flight time. Up to 90 minutes

- Payload capacity. Multiple camera payloads including RGB and multispectral

- Coverage. Up to 500 ha in a single flight

- Launch method. Hand-launched

Learn more about the senseFly eBee X.

Powerline Drone Inspection Software & Apps

Powerline drone inspection software turns raw aerial data into actionable insights.

These tools plan missions, process visual and thermal imagery, detect defects automatically, and create digital twins for better asset management.

For utilities, the right software improves speed, accuracy, and safety by reducing manual review time and standardizing how inspection data is stored and shared.

Here are the top options on the market:

1. Skydio 3D Scan

Type: AI inspection and autonomy software

Skydio 3D Scan enables autonomous capture of complex structures with minimal pilot input. For powerline inspections, it ensures consistent coverage of towers, conductors, and insulators while avoiding obstacles with precision.

Top Use Cases:

- Automated tower and pole capture

- Close-range inspections in cluttered environments

- Consistent image capture for defect detection

- Repeatable data collection for change monitoring

Key Capabilities:

- AI-driven obstacle avoidance

- Automated flight path generation around assets

- Uniform overlap for high-quality 3D reconstruction

- Integration with inspection workflows

Learn more about Skydio 3D Scan.

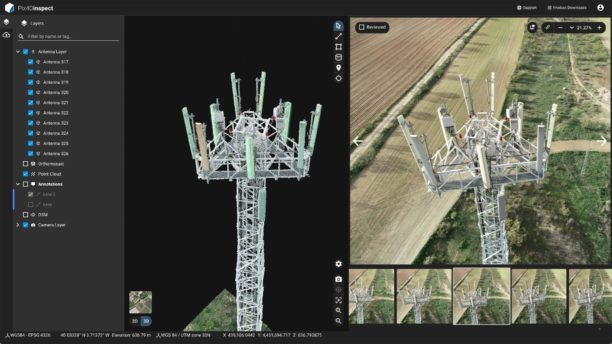

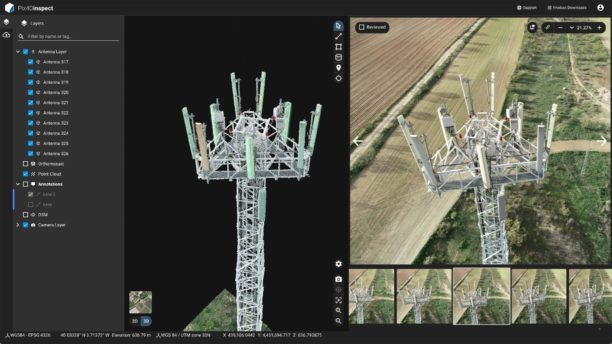

2. Pix4D

Type: AI-powered inspection and asset management platform

Pix4D automates defect detection and asset inventory creation from drone imagery. Its AI tools are optimized for utility structures, making it a strong fit for identifying anomalies on powerlines and towers.

Top Use Cases:

- Transmission and distribution tower inspections

- Automated defect flagging

- 3D asset model creation

- Maintenance planning and reporting

Key Capabilities:

- Automatic component recognition

- 3D model generation from drone imagery

- AI-based defect detection

- Customizable inspection templates

3. DJI Terra

Type: Photogrammetry and mapping software

DJI Terra processes drone imagery into 2D maps and 3D models for inspection and planning. For powerlines, it enables accurate terrain and corridor mapping to support maintenance and construction.

Top Use Cases:

- Transmission corridor mapping

- Vegetation encroachment analysis

- 3D modeling of towers and substations

- Pre-construction planning

Key Capabilities:

- Real-time 2D mapping

- High-accuracy 3D reconstructions

- Multi-sensor data compatibility

- Seamless integration with DJI drones

Drone Powerline Inspection Costs

The cost of a drone powerline inspection varies widely depending on project scope, terrain, equipment, and whether the work is outsourced or handled in-house.

Utilities must consider not just the price per inspection but also the long-term implications for safety, speed, and operational efficiency.

Keep reading for different ways to think about the cost of doing powerline drone inspections.

Cost for Utilities Hiring a Drone Service Provider

Hiring an experienced drone service provider can be cost-effective for utilities that only need periodic inspections.

Typical rates for drone powerline inspections range from $300 to $2,000 per mile, depending on factors like sensor requirements, vegetation density, and accessibility. Smaller projects may be priced per structure, often between $150 and $500.

Costs are influenced by:

- Sensors. Adding thermal, LiDAR, or corona detection increases rates.

- Regulatory approvals. BVLOS operations will add planning costs.

- Geography. Remote or rugged areas can require additional mobilization fees.

- Deliverables. Detailed engineering reports or 3D models cost more than raw imagery.

Travel, lodging, and mobilization fees can add thousands to a project, especially for utilities with dispersed assets.

Cost for Utilities to Operate In-House

Running an in-house program requires a higher upfront investment but can lower the powerline inspection drone cost over time if utilization rates are high.

Major expenses include:

- Drone platform + payload. $13,000–$30,000 for professional-grade systems.

- Pilot and analyst training. $1,500–$5,000 per person for FAA Part 107 prep and inspection-specific courses.

- Software licensing. $3,000–$10,000 annually for mapping, AI defect detection, and asset management tools.

- Maintenance and insurance. $2,000–$5,000 annually per aircraft.

An in-house program might require $25,000–$50,000 in startup costs and $10,000–$20,000 in annual operating expenses. Over time, these costs can be offset by reduced reliance on outside contractors and faster turnaround for inspections.

How to Choose

For many utilities, the choice between outsourcing and in-house operation comes down to inspection frequency, crew availability, and regulatory approvals.

A high-volume inspection schedule favors internal programs, while low-frequency needs may be more cost-effective with a service provider.

Credit: DJI

Jobs & Careers in Drone Powerline Inspections

Drone powerline inspection work is one of the fastest-growing segments of the utility inspection market.

As utilities replace traditional helicopter and climbing inspections with drones, the demand for skilled operators and data specialists is increasing both in the U.S. and internationally.

Drone Powerline Inspection Jobs

In the U.S., demand for drone powerline inspection professionals is rising as major utilities integrate UAS into their asset management strategies. Similar growth is occurring globally, particularly in regions with vast transmission networks like Canada, Australia, and parts of Europe and Asia.

Employers include electric utilities, drone service providers specializing in infrastructure inspections, and engineering firms contracted for grid maintenance.

Roles vary from field pilots capturing visual and thermal imagery to data analysts reviewing inspection results and program managers overseeing operations at scale.

Drone Powerline Inspector Salary

Salaries for powerline drone inspections vary based on experience, certifications, and location (i.e., regional market conditions).

The highest-paying opportunities tend to be in areas with strong utility investment and challenging inspection environments.

In the U.S., entry-level powerline inspection drone pilots typically earn $50,000–$65,000 annually, with mid-level professionals making $65,000–$85,000. Senior inspectors or program managers can command $90,000–$120,000 or more, especially if they manage BVLOS operations or specialized payloads like LiDAR or corona detection.

In Europe, average salaries for similar roles range from €40,000–€70,000 (about $43,600–$76,300), while in the Asia-Pacific region, skilled inspectors can expect between $40,000–$75,000 depending on location and demand.

Powerline Inspection Drones FAQ

Here are answers to the most commonly asked questions about powerline inspection drones.

What is the best drone for utility inspection?

The best drone depends on inspection scope, terrain, and required sensors. Multi-purpose platforms like the DJI Matrice 350 RTK handle a wide range of tasks, while specialized models like the senseFly eBee X excel at large-area corridor mapping.

How can drones improve the safety of pipeline and power line inspections?

Drones replace climbs and helicopter flights with remote aerial data collection, reducing the risk of falls, electrocution, and aviation accidents. Crews can inspect energized assets from the ground, minimizing exposure to hazardous environments.

What is the cost of drone powerline inspections?

Hiring a service provider typically costs $300–$2,000 per mile or $150–$500 per structure, depending on terrain, sensors, and reporting needs. In-house programs involve higher startup costs for equipment and training but can reduce per-inspection costs over time.

Do you need special training to fly a powerline inspection drone?

In the U.S., a valid FAA Part 107 Remote Pilot Certificate is required for commercial operations. Many utilities also require safety training for working near energized lines, along with certifications in thermography, LiDAR operation, or other specialized skills.

What sensors are used for powerline inspections?

Common sensors include high-resolution RGB cameras for visual inspections, thermal cameras to detect hotspots, LiDAR for 3D mapping and vegetation clearance analysis, and corona discharge detectors for identifying electrical faults invisible to the naked eye.

Can drones perform powerline inspections in bad weather?

Most professional powerline inspection drones are rated for moderate wind and light rain, but extreme weather such as heavy rain, snow, or high winds can limit operations. Utilities often schedule flights around safe weather windows to ensure data quality and equipment protection.

Do drone inspections require shutting down power lines?

Many drone inspections can be performed while lines remain energized, reducing downtime. However, certain close-range inspections or repairs may still require de-energizing for crew safety.

How long does a typical drone powerline inspection take?

A small distribution line inspection can take under an hour, while a multi-mile transmission corridor may require several hours or days depending on distance, terrain, and data requirements. Automated flight planning helps speed up larger projects.